25 May 2023

WHAT’S NEW

0 Comment

25 May 2023

WHAT’S NEW

0 Comment

What is Hydraulics

Hydraulics is a branch of engineering that deals with the mechanical properties and use of fluids, in engineering applications. It involves the study of fluid mechanics and the principles of fluid behavior under pressure and flow.

Hydraulic systems utilise the properties of fluids, typically oil or water, to transmit and control power. These systems are widely used in various industries and applications, including construction equipment, manufacturing machinery, aircraft, automobiles, and many others.

The fundamental principle of hydraulics is Pascal’s law, which states that when pressure is applied to a fluid in an enclosed system, the pressure is transmitted equally in all directions. This principle allows hydraulic systems to transmit and amplify forces from one point to another by using fluid pressure.

Hydraulics is a versatile technology that offers advantages such as high power density, precise control, and smooth operation. It has become an integral part of various industries, providing efficient and reliable power transmission and control in a wide range of applications.

What have Yuken contributed to the world of Hydraulics?

Yuken Europe Ltd is a subsidiary of Yuken Kogyo Co., Ltd., a Japanese multinational company specializing in hydraulic equipment and systems. Yuken Kogyo Co., Ltd. was founded in 1928 and has since established a global presence in the hydraulics industry.

Yuken Europe Ltd operates as the European headquarters for Yuken and is located in the United Kingdom. They are responsible for the distribution, sales, and support of Yuken hydraulic products and solutions across Europe.

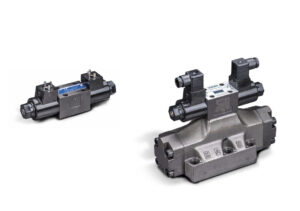

Yuken Europe offers a wide range of hydraulic products, including pumps, cylinders, power units, and systems. Their product portfolio caters to various industries, such as manufacturing, machine tools, construction, marine, and agriculture. Yuken’s hydraulic components are known for their reliability, precision, and performance.

In addition to product distribution, Yuken Europe provides technical support, training, and engineering services to their customers. They work closely with OEMs (Original Equipment Manufacturers) and end-users to develop customised hydraulic solutions that meet specific requirements.

As a part of the Yuken Kogyo group, Yuken Europe benefits from the company’s extensive research and development capabilities, ensuring that their hydraulic products are designed and manufactured using the latest technologies and industry standards.

Over the past 10 years, there have been several notable advances in hydraulic systems.

Here are some key developments:

- Electrically Controlled Hydraulic Systems: There has been a significant shift towards electrically controlled hydraulic systems, often referred to as electro-hydraulic systems. These systems use electronic control units (ECUs) to precisely regulate hydraulic functions, resulting in improved efficiency, performance, and safety.

- Intelligent Hydraulic Systems: The integration of sensors, actuators, and advanced control algorithms has led to the development of intelligent hydraulic systems. These systems can monitor various parameters such as pressure, temperature, and flow rate in real time, enabling adaptive control and optimised performance.

- Energy-Efficient Hydraulic Components: Efforts have been made to improve the energy efficiency of hydraulic components. For instance, hydraulic pumps and motors have been designed with better internal efficiency, reducing energy losses and improving overall system efficiency.

- Digital Hydraulic Systems: Digital hydraulic technology has gained prominence in recent years. By using digital valves and advanced control algorithms, digital hydraulic systems can achieve precise and programmable control of hydraulic flow and pressure, resulting in improved efficiency and performance.

- Reduced Noise and Vibration: Advancements in hydraulic system design and component manufacturing have led to reduced noise and vibration levels. This has been achieved through improved pump and valve designs, enhanced sealing technologies, and better system integration techniques.

- Condition Monitoring and Predictive Maintenance: The incorporation of sensors and data analysis techniques has enabled condition monitoring and predictive maintenance in hydraulic systems. By continuously monitoring parameters such as temperature, pressure, and fluid quality, potential issues can be identified early, allowing for proactive maintenance and minimising downtime.

- Environmentally Friendly Hydraulic Fluids: Hydraulic fluid formulations have evolved to meet stricter environmental regulations and reduce ecological impact. Bio-based and synthetic fluids with improved biodegradability and lower toxicity have gained popularity as alternatives to conventional petroleum-based fluids.

- Compact and Lightweight Hydraulic Systems: There has been a push towards developing compact and lightweight hydraulic systems, particularly in industries such as mobile equipment and aerospace. This has been achieved through innovative component design, the use of lightweight materials, and optimized system layouts.

These are just a few examples of the hydraulic advances that have taken place over the past decade. The field continues to evolve, driven by the need for improved performance, efficiency, and sustainability in various industries.

At Yuken Europe we were so pleased to be part of such pioneering work, paving the way for the next generation of hydraulic engineers.

Yuken is recognised globally for its outstanding products and bespoke services

- Yuken offers a bespoke service in design and build of new devices for customers

- Yuken listens to customers to fully understand your needs

- Yuken Europe Hydraulic Specialists provides the very best solutions helping you to face challenges head-on

To speak to an expert today contact us